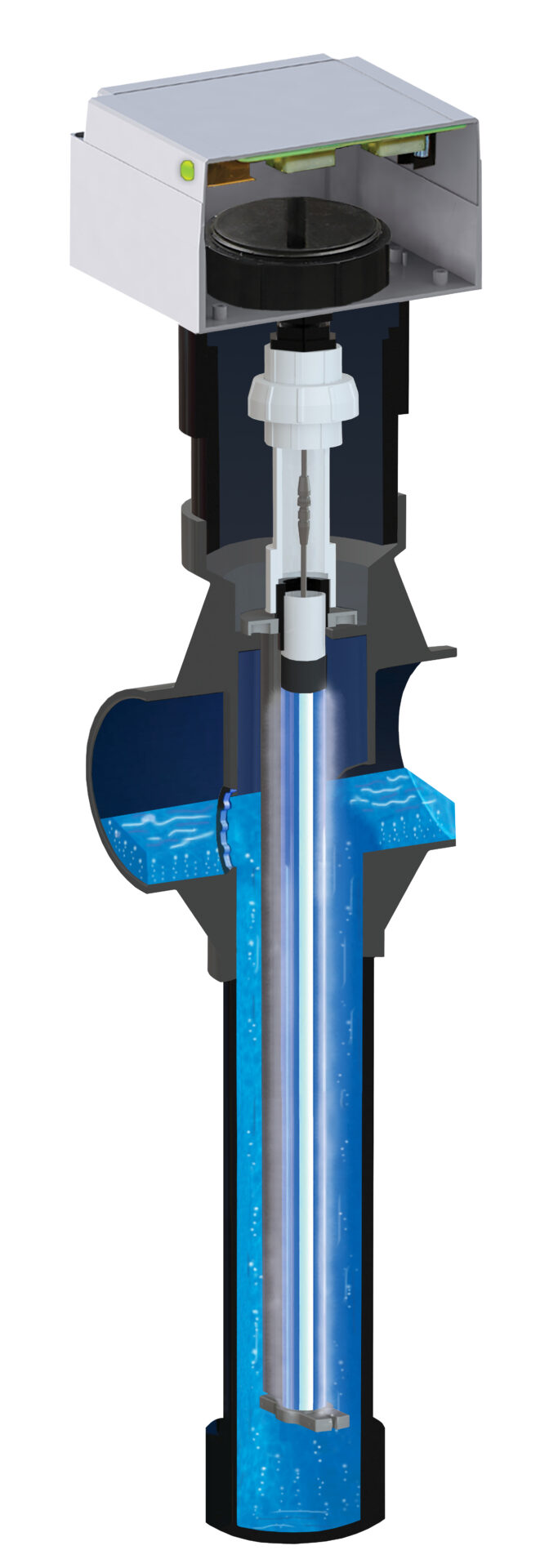

Description

Complete Norweco AT1500 UV Unit.

The Model AT 1500 Ultraviolet (UV) disinfection system provides reliable treatment without chemical addition. The Model AT 1500

UV disinfection system reduces harmful pathogenic bacteria levels tobelow recreational water quality standards.

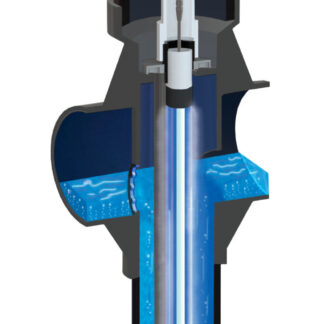

The Model AT 1500 Ultraviolet (UV) disinfection system provides reliable

treatment without chemical addition. A complete treatment unit, the

Model AT 1500 UV disinfection system reduces harmful pathogenic bacteria

levels below bathing water quality standards, particularly with the

high quality effluent provided by the Singulair Bio-Kinetic Wastewater

Treatment Plant. The compact design of the system minimizes the amount

of excavation required making installation quick and easy. Ultraviolet

disinfection is routinely used in ecologically sensitive areas where

residuals from chemical disinfection could possibly create problems in

the receiving environment.